MIF Infrastructure composite panels, which incorporate the original Acme panel, are bespoke, made to precise survey measurements carried out by our experienced survey team. The panel system is designed to fulfil a wide range of applications including Railway Platforms, Walkways, Subways, Over Bridge Spans and Landings and for work access platforms and walkways.

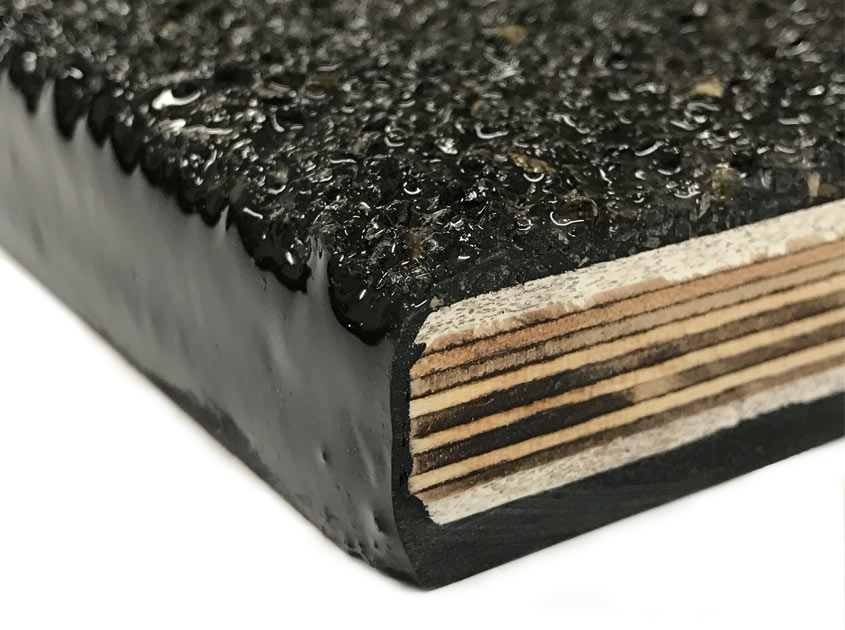

Engineering grade plywood manufacturing technology has significantly improved over recent years and MIF have combined this technology with other composite materials and launched a range of overlay and structured flooring panel products to provide greater strength and functional longevity.

The top coat resin system can be re-applied in situ localised worn areas to extending even longer the design life of the MIF Infrastructure composite Panel system.

Features

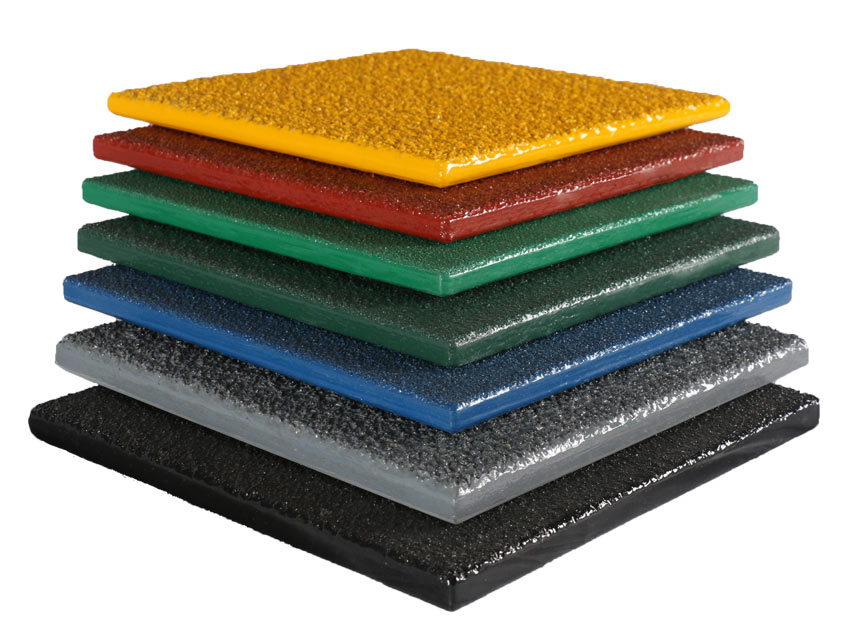

- Extensive range of colours

- Bespoke panel and tread sizes

- Choice of thickness for structural or overlay requirements

- Slip resistant surfaces, from light pedestrian to heavy vehicular traffic

- Lightweight construction

- Chemical and stain resistant

- Non-conductive

- Impact and chip resistant

- Thermal range resistant and insulating

- Tough and durable – long design life

- Quick installation – minimal down time

- Optional Compliance to the Equality act 2010 to BS8300 document “M”. Slip resistant sight lines typically in ultra violet resistant white or yellow resin can be supplied to provide a good visual contrast and highlight the edge

- Optional fire retardancy to BS476 part 7 class 2 vertical surface spread of flame, EN ISO 9239-1 horizontal surface spread of flame and EN ISO 11925-2 ignitability test

- Manufactured under BS EN ISO 9001 Quality controlled conditions

Benefits

- Light weight – reduces frame fabrication.

- Chemical and stain resistant – maintains fresh appearance.

- Non-conductive

- Impact resistant for durability

- Thermal range resistant improved insulating

- Tough and durable with a design life up to 25 years.

Pre-drilled fixing positions, are available with counterbore or countersunk profiles dependant on the fixing type used. Resin kits are provided to fully coat fixing points for aesthetics and security.

MIF Infrastructure composite panels are available with a sealant notch, allowing a foam bead to be fitted during installation to prevent sealant from seeping between panel joints contaminating or damaging objects below.

MIF Infrastructure composite panels are supplied with all necessary stainless steel fixings.

The top coat resin system can be re-applied in situ localised worn areas to extending even longer the design life of the MIF Infrastructure composite Panel system.

Transition Panel edges can be machined to provide a bull nose, chamfer or arris cut edge, typically 2mm to 100mm profile.

Available with a sealed or open profile.

Confirms to the Equality act 2010 to BS8300 document “M”.

Slip resistant sight lines typically in ultra violet resistant white or yellow resin can be supplied to provide a good visual contrast and highlight the edge.

Water and boil proof laminate glues resist moisture penetration into the panel core.

Load bearing cross section.

MIF range of infrastructure composite panel products can be manufactured in a range of highly stable UV colour fast pigments or resins, in a semi gloss or matt finish.

MIF Infrastructure composite panels are supplied with all necessary stainless steel fixings.

The engineering performance of the composite system can be modified with the incorporation of fibre reinforcement